| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : ShiTan

Model Number : GK-200

Certification : ISO9001

Place of Origin : China

MOQ : Negotiation

Price : Negotiation

Payment Terms : L/C, D/A, T/T, Western Union

Supply Ability : 2000Set/Year

Delivery Time : Within 7-12 days

Packaging Details : Standard export transportation package

Production Name : 200 Meters 75mm Hole Diameter Portable Engineering Core Exploration Drill Rig

Model : GK-200

Voltage : 220v

Weight : 600kg

Dimension(L*W*H) : 1730*860*1360

Application : coring machine

Usage : geological core drilling and physical engineering

Color : Customised

OEM : Acceptable

Warranty : 12 months from the date of delivery

200 Meters 75mm Hole Diameter Portable Engineering Core Exploration Drill Rig

GK 200 Core Drilling Rig Introduction

The GK-200 drilling rig is a kind of widely used and hydraulic feeding drill, which has the characteristics of big power, great lifting force (2T) and high transmission torque.is a lightweight shallow hole rig with oil pressure feed. Suitable for census exploration, geophysical exploration, road and building exploration, and small well drilling.

| Drilling Rig Model | |

| Drilling diameter(mm) | 75,91,110,130,150,300 |

| Drilling depth (m) | 200,150,100,70,50,30 |

| Drill pipe diameter (mm) | 42,50 |

| Drilling angle(°) | 90~75 |

| Equipment size(L * B * H) | 1730 * 860 * 1360 (mm) |

| Rig weight (except engine) | 700 |

| Mobile device | |

| Moving length | 350mm |

| Leave distance | 300mm |

| Gyrator | |

| Spindle speed (four gear) (r/min) | 115,230,505,1010 |

| Spindle travel(mm) | 450 |

| Spindle no-load lifting maximum moving speed(m/s) | 0.05 |

| Spindle no load drop maximum movement speed(m/s) | 0.067 |

| Spindle maximum feed pressure(KN) | 15 |

| Spindle maximum lifting force(KN) | 25 |

| Spindle maximum output torque(KN• m) | 1.5 |

| Winch assembly | |

| Winch maximum lifting force (single rope) | 20 |

| Reel speed (r/min) | 20,39,85,170 |

| Reel circumferential speed(m/s) | 0.172, 0.345, 0.738, 1.476 |

| Reel diameter(mm) | 140 |

| Wire rope diameter(mm) | 9.3 |

| Wire rope density (m) | 40 |

| Brake diameter(mm) | 278 |

| Brake band width (mm) | 50 |

| Pump type | Horizontal single cylinder double acting |

| Maximum displacement (motor)(L/min) | 95 (77) |

| The maximum allowable pressure (Mpa) | 1.2 |

| Work pressure (Mpa) | 0.7 |

| Cylinder diameter (mm) | 80 |

| Piston stroke(mm) | 100 |

| Oil pump | |

| Oil pump type | YBC-20/125 |

| Nominal pressure (Mpa) | 12.5 |

| Rated flow(ml/r) | 20 |

| Rated speed(r/min) | 800-2500 |

| Diesel engine or motor | |

| Diesel engine | 1110 |

| Rated power (KW) | 16.2 |

| Rated speed (r/min) | 2200 |

| Rated pressure(Mpa) | 12.5 |

| Motor type | Y160M - 4 |

| Rated power (KW) | 11 |

| Rated speed (r/min) | 1460 |

GK 200 Core Drilling Rig Shining Points

A.53*59 drilling rod adopted,high rigidity and strong delivery torque.

the machine is equipped with national patent technology---taper clutch,with characteristic of strong transmission torque,easy operation and free maintenance.

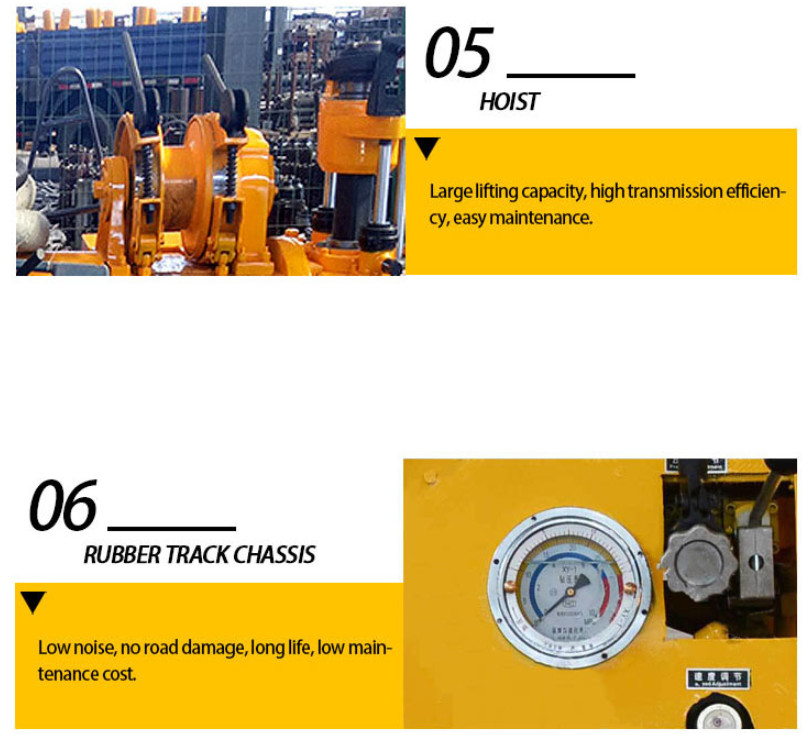

B.for the winch,we use large module planetary gear and add supporting frame,greatly increasing hoisting and braking ability of the winch.

C.vertical spindle are fixed by four groups of bearings to ensure that the rotary machine is rigid enough for gravel layer and other complex geoloical conditions.

D.to equip with the flow 160L/min mud pump so that it will save cost and also make the machine compact,moblie and lightweight.

The principle of core drilling machine

The principle of core drilling machine is basically the same, and the main components are drilling machine, drill pipe, drill bit, etc. The drill provides power to drive the drill pipe and drill bit to drill and obtain deep core samples. According to different depths and strata, corresponding to different types of drilling rigs, xy-100 is a common model

How to solve the problem of sand layer when drilling?

Experienced drilling masters will mix a pool of mud for standby in advance and replace it in time before reaching the sand layer. When the bit passes through the sand layer, the mud will paste the sand,how do you like this method?Welcome your opinion and comment ,thank you for sharing.

|

|

200 Meters Diamond OEM Core Drill Rig 75mm Hole Diameter Mining Images |